Robotic Gripper Arms – End of Arm Tooling (EOAT) Grippers for Your Plastic Injection Molding Process

Plastic Manufacturing automation, particularly in plastics production, plays an indispensable role in contemporary engineering endeavors. Whether it’s for household items, electronics, automotive components, or myriad other applications, plastics are ubiquitous. Gripper arms, specifically end-of-arm tooling (EOAT) grippers, are integral components of these systems, adept at grasping, securing, and maneuvering parts with precision throughout the assembly line. Continue reading to delve into the world of robotic gripper arms, the accompanying EOAT devices, and the terminology essential for navigating the optimal solutions tailored to your distinct plastics manufacturing requirements

What Are Robotic Arm Grippers?

Robotic systems employed in automation are tasked with a multitude of functions, tailored to suit the distinct requirements of your manufacturing processes. The overarching term “robotic arm” encompasses the complete apparatus and is occasionally utilized interchangeably with “gripper.” Nonetheless, within industrial lexicon, a gripper denotes a precise device utilized in end-of-arm tooling, distinct from the entirety of the robotic arm.

End-of-arm (EOAT) tools encapsulate a range of attachments affixed to the terminus of this arm, with a specific subtype being the gripper.

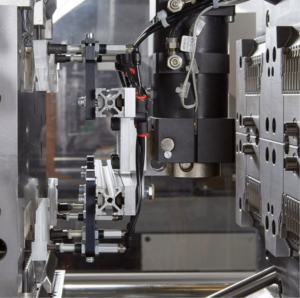

In the realm of plastic injection molding, the robotic gripper and its accompanying arm ( EOAT )emerge as indispensable components. Serving as distinctive end effectors, they undertake the crucial tasks of installing and extracting parts along assembly lines. Effectively functioning as the digital appendages of your robotic assemblers, these devices empower them with the capability to grasp, reposition, and deposit objects with unwavering accuracy.

Gripper arms serve a pivotal role in the manipulation and extraction of plastic components throughout the assembly procedure, including the final step of removing them from the mold. Affixed to the extremity of injection molding machines, they are aptly termed end-of-arm tooling.

Within the mold lies a cavity into which the plastic is injected. Subsequently, the gripper arm is employed to extract the plastic from the mold and relocate it to another site. Moreover, the gripper arm facilitates the extraction of the plastic from the mold for inspection, allowing for thorough scrutiny of potential defects.

Types of Robotic Gripper Arms for Plastic Molding Processes

Vacuum Gripper

Often labeled as “robotic arm vacuum grippers,” vacuum grippers utilized in end-of-arm tooling represent a specific category of gripper that employs vacuum suction to hoist and maneuver objects. By harnessing negative pressure generated through electromechanical or air-driven pumps, these grippers facilitate automation across a spectrum of scales, accommodating processes of varying magnitudes.

Vacuum gripper end effectors excel in plastic injection molding and other plastic manufacturing due to the likelihood of flat surfaces, where vacuum grippers can safely grab the object and leave no chance for scratching or scraping of the plastic. Likewise, plastic material tends to be used in lightweight production, where vacuum grippers won’t need to produce a great deal of negative pressure to properly function.

Parallel Gripper

Parallel grippers are a type of end of arm tooling that utilize two parallel surfaces to grip objects. The advantage of parallel grippers in plastics manufacturing is precision and rigidity during the automation process.

One unique aspect of parallel gripper end effectors is the ability to use sensors to monitor their payload, allowing the automation process to accurately track the status of the grippers, from pickup, to placement, to even potential issues like a dropped payload.

Sprue Gripper for Plastics

In plastic molding processes, sprues play a common role. Once the product is finalized, the removal of sprues becomes necessary. Sprue grippers are meticulously crafted to excel in this task, often featuring textured gripping surfaces that enable them to securely hold even the smallest of sprues.

ID (Inner Dimension) Gripper

Occasionally referred to as an expansion gripper, this variant of end effector, attached to a robotic gripper arm, is engineered to enter a cavity and subsequently expand. It harnesses this expansion force to firmly grasp onto an object, which proves advantageous for processes necessitating accessible exterior surfaces. Such applications span from subsequent assembly tasks to inspection processes, where accessibility is paramount.

Gripper Fingers

Gripper fingers are an entire category of devices used for EOAT grippers. These function like fingertips and can swivel or clamp behind parts for manufacturing processes.

MARKROBOTIC With our profound expertise in plastics manufacturing, we offer tools and systems meticulously crafted to elevate your plastic assembly and injection molding processes to optimal efficiency. Whether you’re navigating plastics applications or injection molding tasks, our product line presents the most comprehensive array of grippers and other end-of-arm tooling devices tailored to meet your exacting requirements. Our extensive selection of readily available, in-stock parts ensures swift delivery. Additionally, we stand ready to collaborate with you in designing bespoke, made-to-fit solutions for your unique process needs, including leveraging cutting-edge 3D printing services. Reach out to us today to embark on your journey towards streamlined plastic manufacturing excellence!

Visit markrobotic.com to connect with our knowledgeable professionals and discover how we can meet your unique needs.

MARKROBOTIC LTD COMPANY Has more than 14 years of experience and is well known for high-performance IML ROBOT ,EOAT System , TOP ENTRY ROBOT , Handle Fitting Machines, Medical Automation Systems as well as innovative downstream solutions that include Product/Decoration Inspection, Assembly-and Box Filling Systems.

Headquarter of MARKROBOTIC is based in Istanbul /Turkey , providing superior service and greater overall value to a rapidly expanding global customer base.

For request you can contact with us : WWW.MARKROBOTIC.COM