What’s the future of plastics automation in manufacturing?

The global plastics industry is colossal, boasting a manufacturing-focused market size that consistently exceeds a hundred billion dollars annually. With such substantial financial stakes, businesses and manufacturers operating in the realm of plastics are perennially confronted with a crucial inquiry: what comes next?

The unequivocal response: automation. Plastics automation stands as the cornerstone of both current achievements and future triumphs within the plastics manufacturing sector. Thus, the pertinent question shifts to: what’s on the horizon for plastics automation? Moreover, how can plastics manufacturers ensure that they harness these forward-thinking concepts and technologies to uphold a competitive advantage?

Let’s delve deeper into this inquiry….

What cutting-edge technologies and methods are molding the future landscape of plastics automation ?

Among the array of technologies and techniques already established in plastics automation, two primary driving forces stand out for shaping its future:

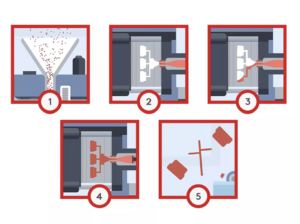

Injection molding : stands as a cornerstone of plastics automation, deeply entrenched within the industry. As we peer into the future of injection molding, three pivotal drivers emerge: advancements in technology, machinery innovation, and evolving customer demands.

Firstly, the evolution of plastics is pivotal in driving advancements. The realm of thermoplastic science is undergoing rapid evolution, necessitating manufacturers to adapt to these novel plastic compositions. The investment in handling these emerging materials proves worthwhile as they offer enhanced attributes such as increased flexibility, heightened heat resistance, varying opacity levels, augmented durability, improved conductivity, customizable appearances, and more.

Secondly, shifting societal priorities influence customer demands profoundly. The events of 2020 have underscored a paramount focus on safety within industrial settings. This has spurred a surge in the production of bacteria-resistant plastics and materials engineered for easier cleaning, sanitization, and maintenance. Rather than abating post-pandemic, these trends persist as the new norm gravitates towards heightened cleanliness standards.

Lastly, technological innovations are shaping the future landscape of injection molding. Constant technological progression characterizes the plastics manufacturing sector. While Industry 4.0 emphasized the integration of technologies to bolster efficiency and productivity, the emergence of Internet 5.0 signals a shift towards advancements in robotics and intelligent machines capable of human-like decision-making. Enhanced monitoring of temperature control and injection pressure through these sophisticated technologies empowers manufacturers with greater precision and minimizes potential quality assurance discrepancies during production. As these technologies evolve to greater levels of sophistication and intelligence, the present moment presents an opportune time to explore avenues for leveraging robotics and AI to enhance automation processes.

Sustainability : is emerging as a central theme in discussions surrounding the future of plastics. Key areas of discourse encompass the challenges encountered by diverse industries in achieving sustainability goals, the ongoing efforts towards developing eco-friendly packaging solutions, advancements in bioplastics, and the optimization of materials to minimize environmental impact. Complementing these discussions are strategic approaches to automation that leverage technology to mitigate plastic waste and enhance operational efficiency, thus paving the way for sustainable plastics automation in the future.

In the realm of plastics, the trajectory ahead points towards a greener future. Businesses striving to maintain competitiveness are increasingly focusing on avenues to innovate in their creation, manufacturing, and overall operations to align with sustainable practices.

What strategies should manufacturing businesses implement to maintain competitiveness in the evolving market landscape?

To maintain competitiveness, it’s crucial to stay informed and engaged. Stay updated by reading industry publications, following industry influencers, and actively participating in relevant discussions on social media platforms. By staying attuned to industry trends and insights, you can better position your plastics company for success.

Additionally, forging strategic partnerships with companies specializing in plastics automation can greatly enhance your competitive edge. Seek out partners like MARKROBOTIC LTD COMPANY , renowned for their tailored, end-to-end solutions in plastics automation that align with forward-thinking strategies. If you’re interested in learning more about how our plastics automation processes can benefit your business, don’t hesitate to reach out to us today. We’re here to address any inquiries you may have and help propel your company towards future success.

MARKROBOTIC LTD COMPANY Has more than 14 years of experience and is well known for high-performance IML ROBOT ,EOAT System , TOP ENTRY ROBOT , Handle Fitting Machines, cobot robot , Medical Automation Systems as well as innovative downstream solutions that include Product/Decoration Inspection, Assembly-and Box Filling Systems.

Headquarter of MARKROBOTIC is based in Istanbul /Turkey , providing superior service and greater overall value to a rapidly expanding global customer base.