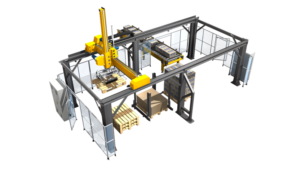

Gantry Systems-TOP Entry Robot.

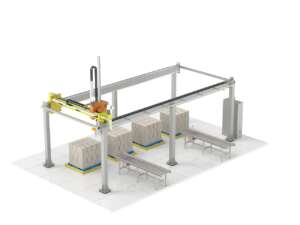

Gantry systems, featuring a movable trolley gliding along a linear bridge, stand as pivotal tools in industrial settings, revered for their exceptional precision, rapidity, and versatility.

Introduction

Gantry systems have become indispensable across various sectors, revolutionizing manufacturing, logistics, and automation workflows. With their unparalleled precision, agility, and adaptability, these systems offer a myriad of advantages, enhancing operational efficiency and facilitating seamless processes. This comprehensive overview aims to delve into the intricacies of gantry technology, exploring its components, diverse applications, design nuances, and maintenance protocols.

Undoubtedly, the significance of gantry systems in modern industries cannot be emphasized enough. Continuously evolving alongside technological advancements, these systems redefine operational paradigms, empowering businesses to streamline their processes and stay ahead in competitive markets. By delving into the operational dynamics and technical intricacies of gantry robotics, enterprises can strategically incorporate these solutions, unlocking new levels of productivity and performance.

Gantry System: Basic Components

A gantry system is a mechanical structure that consists of various components working together to enable precise and controlled multi-axis linear motion. Understanding these components and their functions is essential to the proper design, implementation, and maintenance of gantry systems. The basic components of a gantry system include linear rails, bearings and slides, motors and drives, and control systems and software. Each of these components plays a vital role in the overall performance of the system, and their proper selection and integration are crucial for achieving desired results.

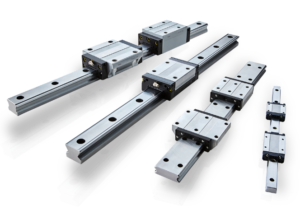

MARKROBOTIC used famous brands like THK – Rexroth –HIWIN and INA .

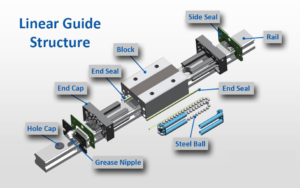

1.Linear Rails:

Linear rails, also referred to as linear guide rails or guideways, serve as the foundational framework for linear robots, providing essential support and direction to the system’s mobile elements. These rails facilitate seamless and accurate movement along predefined trajectories, ensuring precise positioning and minimal resistance.

Diverse types of linear rails exist, encompassing round, profiled, and V-shaped variants. Round rails represent a straightforward and cost-effective choice, furnishing basic guidance for gantry system constituents. Conversely, profiled rails boast a sophisticated design, characterized by heightened precision and load-bearing capabilities. Featuring meticulously machined surfaces with specific profiles matched to corresponding bearing blocks, these rails excel in demanding applications. Meanwhile, V-shaped rails offer a distinctive blend of robustness and self-alignment, simplifying installation and upkeep processes.

In the process of selecting linear rails tailored to a specific application, numerous considerations come into play. Critical factors encompass the requisite load-bearing capacity, desired system velocity, and precision requirements, alongside the environmental conditions dictating operational parameters. For instance, applications demanding robust performance may necessitate the utilization of profiled rails, renowned for their exceptional load-bearing capabilities. Conversely, scenarios emphasizing rapid motion could benefit from the low-friction properties and heightened rigidity characteristic of V-shaped rails. Moreover, in environments characterized by harsh conditions such as elevated humidity or exposure to corrosive substances, employing linear rails treated with specialized coatings or crafted from corrosion-resistant materials becomes imperative to ensure prolonged durability and reliable performance.

2.Bearings and Linear Slides:

Bearings and linear slides constitute indispensable elements within gantry systems, serving as the linchpins for orchestrating seamless and regulated motion along the linear rails. Tasked with mitigating friction between dynamic components, they play a pivotal role in guaranteeing precise positioning while mitigating wear on vital system elements. The selection of appropriate bearings and slides bears substantial ramifications on the system’s holistic performance, durability, and maintenance exigencies.

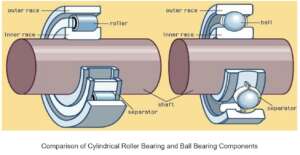

There are various types of bearings and linear slides available, each with its own unique characteristics and advantages. Some common types include linear ball bearings, roller bearings, and sliding bearings.

Linear ball bearings stand as the preeminent choice among bearings employed in gantry systems, renowned for their exemplary precision and minimal friction. Comprising a succession of ball bearings encased within a bearing block, they traverse the rail with seamless fluidity. Their versatility extends across a broad spectrum of applications, spanning from lightweight systems to robust counterparts engineered to withstand substantial loads. Noteworthy for their exceptional rigidity and enduring service life, linear ball bearings enjoy widespread adoption across diverse industrial sectors.

Roller bearings, on the other hand, use cylindrical or needle rollers instead of ball bearings to facilitate motion. They offer higher load capacities and greater rigidity compared to linear ball bearings, making them well-suited for heavy-duty applications. Roller bearings are also less susceptible to contamination, as their design prevents the ingress of dirt and debris.

Sliding bearings, also known as plain bearings or bushings, rely on a smooth sliding motion between two surfaces, typically with the help of a lubricant. They offer a simple and cost-effective solution for low-speed and low-load applications, where precision is not a critical factor. Sliding bearings are also self-lubricating, which can result in lower maintenance requirements.

When deliberating on the selection of bearings and slides for a gantry system, meticulous attention must be paid to an array of critical factors encompassing load capacity, velocity, precision, and prevailing environmental circumstances. Tailoring the choice of bearings and slides to the unique demands of the application is paramount, considering their potential ramifications on overall system efficacy, longevity, and maintenance prerequisites. Furthermore, meticulous installation and alignment procedures are imperative to guaranteeing the seamless and dependable operation of the bearings and slides, thus underlining their pivotal role in the system’s performance and durability.

3.Motors and Drives:

Motors and drives represent indispensable constituents within gantry robot systems, assuming the crucial responsibility of furnishing requisite force and precision to propel the motion system’s components along the linear rails. Their significance transcends mere functionality, exerting a profound influence on the system’s overarching speed, accuracy, and operational efficiency. A nuanced comprehension of the diverse motor and drive options, coupled with their distinctive attributes, empowers stakeholders to discern and deploy the optimal solution tailored to the exigencies of a given application.

There are several types of motors commonly used in gantry systems, including stepper motors, servo motors, and linear motors. Each of these motors offers its own set of advantages and drawbacks, depending on the requirements of the application.

Stepper motors emerge as a favored option for numerous gantry systems owing to their trifecta of simplicity, precision, and cost-effectiveness. Functioning by subdividing a complete rotation into myriad discrete steps, these motors facilitate meticulous regulation over both position and velocity. Renowned for their aptitude in applications mandating exacting positioning and moderate speeds, such as 3D printing and CNC machining, stepper motors epitomize versatility and reliability in the realm of gantry system propulsion.

Servo motors represent a distinct alternative, boasting superior levels of accuracy, speed, and torque in comparison to stepper motors. Distinguished by their utilization of a closed-loop control mechanism, servo motors leverage feedback from sensors to continuously fine-tune their position and velocity. This dynamic responsiveness equips servo motors with the capability to uphold meticulous control amidst fluctuating loads and operational dynamics. Consequently, servo motors find preferential deployment in domains necessitating paramount precision, high-speed operation, and robust torque, exemplified by applications spanning robotics and automation systems.

Linear motors stand out as a distinctive breed, orchestrating linear motion directly instead of the conventional rotational movement. This obviates the necessity for supplementary mechanical components like gears and belts, which typically serve to convert rotational force into linear action. The innate simplicity of linear motors translates into pronounced advantages encompassing heightened speed, precision, and operational efficiency. Consequently, they emerge as the quintessential choice for applications demanding elevated dynamics, swift velocities, and pinpoint accuracy, thus embodying an indispensable solution for high-performance endeavors.

Drives, alternatively referred to as motor controllers, assume the pivotal role of overseeing the power distribution to the motors while governing their speed, direction, and positioning within the gantry system. The selection of drive technology bears substantial ramifications on the system’s overall efficacy and efficiency. Diverse variants of drives abound, encompassing stepper motor drives, servo motor drives, and variable frequency drives (VFDs), each meticulously tailored to harmonize with specific motor types, thereby furnishing the epitome of control and performance requisite for optimal operation.

In the meticulous process of selecting motors and drives for a gantry system, a comprehensive assessment of various factors is imperative, including load capacity, velocity, precision, and prevailing environmental circumstances. Adherence to these considerations is paramount to align the choice of motors and drives with the specific demands of the application, thereby safeguarding against potential disruptions to system performance, optimizing energy efficiency, and mitigating maintenance exigencies. Furthermore, seamless integration of the motors and drives with other components within the gantry system ecosystem is essential to foster harmonious synergy and uphold the hallmark of smooth and dependable operation.

4.Control Systems and Software:

Control systems and software serve as the orchestrators within gantry systems, harmonizing the diverse components including motors, drives, and sensors to actualize precise motion and positioning objectives. Leveraging sophisticated control algorithms and software tools, gantry systems attain unparalleled levels of precision, velocity, and operational efficiency, rendering them indispensable across a broad spectrum of applications.

Typically comprising a blend of hardware and software elements, control systems for gantry systems engender seamless integration and operation. Key constituents encompass a programmable logic controller (PLC), a motion controller, and input/output (I/O) devices, working synergistically to furnish a cohesive and integrated solution for motion control.

A programmable logic controller (PLC) epitomizes a robust and industrial-grade computing entity meticulously crafted to execute control tasks with real-time precision. Renowned for their prowess in managing intricate control operations, PLCs find pervasive adoption within gantry systems, adeptly tackling multifaceted responsibilities such as orchestrating multiple axes of motion, assimilating sensor data, and enforcing critical safety protocols. The inherent flexibility of PLCs endows them with the capacity for seamless customization and adaptation across diverse applications, rendering them an optimal and versatile choice for gantry systems.

Motion controllers represent specialized apparatuses meticulously engineered to oversee the intricate movement and positioning intricacies of motors within a gantry system. Leveraging sophisticated algorithms and real-time feedback gleaned from sensors, these controllers meticulously optimize the motion profile, guaranteeing seamless and precise operation. These controllers can manifest as standalone entities or seamlessly integrated components within a PLC or PC-based control system, showcasing versatility in their application and compatibility across varied operational frameworks.

Input/output (I/O) devices serve as the conduits facilitating seamless communication and data exchange among the diverse components within gantry systems. Examples of I/O devices encompass sensors, displays, and control panels, furnishing indispensable information to the control system for informed decision-making and effective execution of control tasks.

Software assumes a pivotal role in orchestrating the operation of a gantry system’s control, furnishing a user-friendly interface for programming, monitoring, and diagnosing system functionalities. An array of software tools exists, ranging from proprietary solutions provided by gantry system manufacturers to adaptable open-source alternatives. Key software functionalities encompass motion planning, trajectory generation, and error detection and correction, bolstering the system’s efficiency and reliability.

When navigating the selection process for a control system and software tailored to a gantry system, a nuanced evaluation of various factors becomes imperative. Paramount considerations encompass the complexity inherent in motion tasks, the extent of integration required with other systems, and the requisite level of customization. Guided by the specific application requirements, the choice of control system and software should be meticulously calibrated, weighing potential impacts on system performance, user-friendliness, and maintenance exigencies.

Furthermore, meticulous configuration and integration of the selected control system and software with other components within the gantry system ecosystem are indispensable prerequisites for fostering seamless and dependable operation. This holistic approach ensures harmonious synergy among disparate elements, thereby fortifying the system’s operational robustness and reliability.

MARKROBOTIC using famous brands like Schneider –Siemens – Omron and Yaskawa .

In summary, Gantry systems stand as cornerstone elements within the realm of robotics and automation, embodying a fusion of precision, velocity, and adaptability. Through seamless integration with complementary robotic components and cutting-edge control systems, industries stand poised to elevate the performance benchmarks of their robotic systems, unlocking new frontiers of automation across a myriad of applications. From In-Mold Labeling (IML) robotics to welding, machining, inspection, and material handling, the synergistic interplay between gantry systems and allied technologies heralds a paradigm shift towards enhanced efficiency and productivity in industrial operations.

Conclusion

Gantry systems have emerged as indispensable assets across diverse industries, heralding a new era of precision, velocity, and adaptability.

Their versatility finds expression in an array of applications spanning manufacturing, assembly, material handling, logistics, and robotics, underscoring their pervasive impact on modern industrial landscapes. Equipped with a comprehensive understanding of gantry system fundamentals encompassing types, design nuances, and application paradigms, organizations stand poised to unlock transformative potential, optimizing operations and fostering efficiency gains.

The crux of harnessing the full potential of gantry systems lies in discerning the unique requirements inherent in each application domain, coupled with judicious selection from a broad array of available options ranging from Cartesian to polar or cylindrical configurations. Moreover, meticulous attention to factors such as load capacity, system velocity, precision, and environmental variables ensures the seamless integration and optimal performance of gantry systems across diverse operational contexts.

As industries traverse the trajectory of technological evolution, the significance of gantry systems is poised for exponential growth, underpinned by continual advancements in control systems, materials science, and design methodologies. These progressive strides are poised to catalyze innovation, ushering in a new era of unparalleled efficiency and efficacy in industrial practices.

Finally :

MARKROBOTIC LTD COMPANY Has more than 14 years of experience and is well known for high-performance IML ROBOT ,EOAT System , TOP ENTRY ROBOT , Handle Fitting Machines, Medical Automation Systems as well as innovative downstream solutions that include Product/Decoration Inspection, Assembly-and Box Filling Systems.

Headquarter of MARKROBOTIC is based in Istanbul /Turkey , providing superior service and greater overall value to a rapidly expanding global customer base.

For request IML ROBOT OR TOP ENTRY ROBOT you can contact with us : WWW.MARKROBOTIC.COM