How to Choose the Perfect iml robot- Pick and Place Robot for the Plastics Industry

Pick and Place robots are among the most essential solutions in modern plastic manufacturing lines. They provide precision, speed, and operational efficiency, helping factories improve output while reducing errors and downtime.

However, choosing the right robot requires careful consideration of several technical and environmental factors. This guide explains how to select the ideal Pick and Place robot for plastics production, focusing on practical and technical aspects.

1. Define Your Production Requirements

Before selecting a robot, you need to clearly identify your production needs:

-

Type of plastic product: Is it a bottle, cap, container, or a small precision part?

-

Product size and weight: Determines the robot’s payload capacity.

-

Production speed: How many cycles per minute are required?

-

Process type: Does the task require high-precision handling, IML robot (In-Mold Labeling), or fast conveyor transfers?

Clearly defining these requirements ensures you choose a robot with the right speed and payload capacity.

2. Choose the Right Type of Robot

Different types of Pick and Place robots offer distinct advantages:

| Robot Type | Advantages | Ideal Applications in Plastics |

|---|---|---|

| SCARA Robot | High horizontal precision, fast cycle times | Bottling, small packaging, assembly tasks |

| Delta/Spider Robot | Extremely high speed, lightweight, rapid cycles | Small parts like caps, lids, or precision components |

| Articulated Robot (6-DOF) | High flexibility, handles heavy loads | Large molds or complex production lines |

| Cartesian/Linear Robot | Easy installation, cost-effective | Simple pick-and-place or conveyor transfer |

💡 In the plastics industry, Delta and SCARA robots are most common due to their speed and high precision.

3. Determine Accuracy and Control Requirements

Robot accuracy is critical for successful Pick and Place operations:

-

Positional accuracy: Impacts part alignment and IML quality.

-

Repeatability: Ensures consistent performance in high-volume production.

-

Motion control: Ensure compatibility with modern systems such as servo motors or PLC integration.

4. Consider the Production Environment

The factory environment affects the robot choice:

-

Temperature and humidity: Some robots require stable environmental conditions.

-

Space constraints: Choose a robot size that fits the production floor.

-

Dust and contamination: Some plastics processes generate dust or fumes; consider robots with appropriate IP ratings.

5. Integration with Existing Production Systems

A suitable Pick and Place robot must integrate seamlessly with:

-

Plastic injection molding machines

-

Conveyor systems

-

Packaging lines

-

IML robot (In-Mold Labeling) for labeling inside molds

Integration ensures smoother operation and higher productivity.

6. Evaluate Cost vs. ROI

Choosing a robot requires balancing:

-

Robot purchase cost

-

Installation and programming expenses

-

Maintenance and energy consumption

-

Productivity gains and waste reduction

The goal is to select a solution that delivers fast ROI and reduces production errors.

7. Choose a Reliable Supplier

Work with robot suppliers that provide:

-

Fast technical support

-

Availability of spare parts

-

Training for operators

-

Scalable solutions for future upgrades

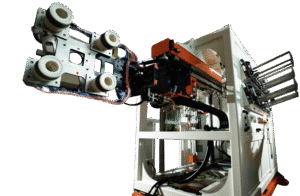

Example: MarkRobotic offers Pick and Place solutions tailored for plastics, including high-speed, precise IML robot for modern production lines.

Conclusion

Selecting a Pick and Place robot in the plastics industry is a strategic investment. The right robot can:

-

Improve productivity

-

Reduce material waste

-

Ensure consistent product quality

By following these steps:

-

Define production requirements

-

Choose the right robot type

-

Ensure accuracy and control

-

Adapt to the production environment

-

Integrate with existing systems

-

Evaluate cost vs. ROI

-

Select a trusted supplier

…any manufacturer can choose a Pick and Place robot that maximizes efficiency and delivers reliable results.

MARKROBOTIC LTD COMPANY Has more than 14 years of experience and is well known for high-performance IML ROBOT ,EOAT System , TOP ENTRY ROBOT , Handle Fitting Machines, cobot robot , Medical Automation Systems as well as innovative downstream solutions that include Product/Decoration Inspection, Assembly-and Box Filling Systems.

Headquarter of MARKROBOTIC is based in Istanbul /Turkey , providing superior service and greater overall value to a rapidly expanding global customer base.