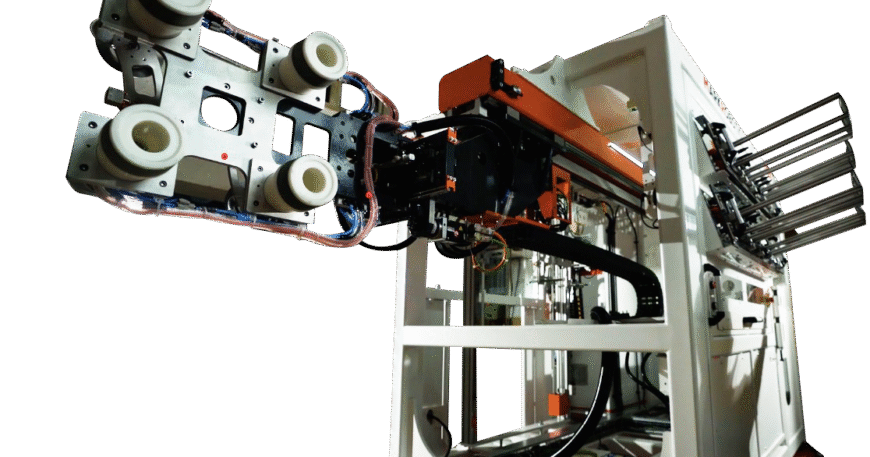

Industry-leading : Side Entry IML robot From MARKROBOTIC

At Markrobotic, we are committed to driving innovation in the robotics and automation sectors, and our Side Entry IML Robot is a game-changer in the world of in-mold labeling (IML). Designed for industries like packaging, plastics, and consumer goods, our side-entry robot brings unmatched precision, speed, and efficiency to automated molding operations.

What is a Side Entry IML Robot?

Our Side Entry IML Robot integrates seamlessly into in-mold labeling (IML) processes, offering precise label insertion during the molding cycle. Unlike traditional systems that rely on top-entry or other robotic configurations, the side-entry design ensures minimal interference with the mold and maximizes production space. This design is ideal for high-volume production lines where speed, accuracy, and flexibility are crucial.

Advantages of MARKROBOTIC IML Side entry :

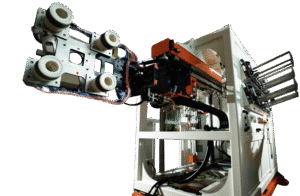

- Standard steel frame with integrated safety housing and safety doors.

- High-speed side-entry robot equipped with dual linear bearings for enhanced stability.

- Stacking unit with a capacity of up to 1,500 mm.

- Dummy core equipped with efficient static charge elements.

- User-friendly label magazine with continuous reloading during production.

- The robot can also be used for producing parts without labels (Just take out).

Applications of the Side Entry IML Robot:

-

Packaging Industry: Perfect for the production of containers, cups, and lids with IML labels.

-

Consumer Goods: Ideal for molding and labeling products like bottles, tubs, and trays.

-

Plastic Manufacturing: Optimized for high-throughput plastic molding applications requiring IML.

Types of Side entry IML ROBOT :

MARKROBOTIC SIDE ENTRY IML ROBOT FOR: F – Flat labels for lids, 3-sided to 5-sided container labels.

MARKROBOTIC SIDE ENTRY IML ROBOT FOR: W – Wrap around labels.

MARKROBOTIC S- Stack Mold IML ROBOT:

- Label magazines mounted on both sides of the robot.

- Conveyor belt positioned alongside the clamping unit.

- Side-entry robots driven by 2 servo motors.

- Compatible with all types of label magazines.

- Molded parts are palletized on the conveyor belt following customized program patterns.

- The robot can also be used for producing parts without labels (Just take out) .

iml robot – TOP ENTRY ROBOT (CARTESIAN) :

Robot Models and Features:

- Robot Range: Robot models range from 1 kg to 60 kg .

- Mounting Options: Robots can be mounted either on the fixed platen of IMM ( or on an external support frame.

- Flexible Design: Engineered for high flexibility, suitable for all types of packaging and pick-place applications , suitable for all IML robot applications, including flat and wrap-around labels.

- Stacking Unit Compatibility: Optional external stacking unit can be integrated as needed.

- Gripper System: Equipped with a quick-coupling gripper for fast and easy changeovers.

- Available with 3 to 5 axis configurations for all application .

- Two types of Z-axis available: single-stage or telescopic stage.

You follow MARKROBOTIC Youtube channel to watch more ..

Why Choose MARKROBOTIC’s Side Entry IML Robot?

At MARKROBOTIC , we are committed to providing cutting-edge robotics solutions that help manufacturers optimize their operations, improve product quality, and reduce operational costs. Our Side Entry IML Robot represents the future of packaging automation, offering a level of precision and efficiency that meets the most demanding manufacturing needs.

If you’re looking to elevate your packaging operations and automate your in-mold labeling process with an efficient, flexible, and cost-effective solution, look no further than MARKROBOTIC’s Side Entry IML Robot.

MARKROBOTIC LTD COMPANY Has more than 14 years of experience and is well known for high-performance IML ROBOT ,EOAT System , TOP ENTRY ROBOT , Handle Fitting Machines, cobot robot , Medical Automation Systems as well as innovative downstream solutions that include Product/Decoration Inspection, Assembly-and Box Filling Systems.

Headquarter of MARKROBOTIC is based in Istanbul /Turkey , providing superior service and greater overall value to a rapidly expanding global customer base.