Cartesian Robot (Top entry) or Side Entry Robot ?

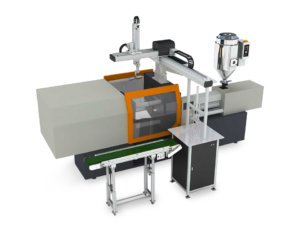

As a company specializing in high speed part removal from injection molding machines and IML ROBOT technologies , we are often asked to justify the price differential between our standard Cartesian ( top entry) robots and our side entry robots.

An installation of our flagship side entry robot costs around double that of a Top entry robot solution, so the aim of this blog is to help you decide which is right for your particular project .

Cycle time :

As a starting point, it’s essential to grasp the concept of a ‘Cycle time’ When evaluating the expenses for a molding venture characterized by being ‘high volume, low margin,’ maintaining a consistent cycle time becomes paramount. Meeting the targeted cycle time consistently, without fail, is crucial to prevent falling short of production demands and incurring losses. Packaging projects serve as a prime illustration of this imperative.

So how fast is fast?

In scenarios where production resembles a hybrid of packaging and other processes (“semi-molding”), the pace is often restricted by thicker wall sections, translating to target cycle times of approximately ten seconds. While a skilled Toolmaker can calculate injection and cooling durations, it’s imperative to also factor in tool opening/closing times and product demolding (take-out) durations.

For authentic high-speed molding endeavors, cycle times can plummet to as low as 5 seconds (IML Technology). This figure encompasses the entirety of the process, encompassing what’s known as “mold delay”—the time interrupted by the robotic activity within the process.

The vital figures

A Top entry robot will struggle to get below 1.0 to 1.2 seconds for take-out cycle time, and Indeed, the bulkier design of the wrist in a Cartesian robot necessitates a wider opening for the tool. This extended movement requirement adds to the overall cycle time, as the robot must cover a greater distance during each cycle. This will extend the cycle time further, as open/close stroke is dead time.

In contrast, standard side entry robots excel in achieving mold delay (take-out) times as swift as 0.5 seconds, with the CFR model even pushing this figure down to an impressive 0.3 seconds.

When producing slim products with minimal depth, side entry units shine as they require virtually no strip stroke, and tool opening can be kept to a minimum. Even with our CFR unit, which excels in handling deeper products, achieving rapid demold times is still feasible. By synchronizing with the tool’s opening, the robot is configured to track its movement, collecting the product as it opens and swiftly exiting the mold with minimal delay.

The culmination of these factors allows side entry robots to effortlessly achieve cycle times as low as 5 seconds, while Cartesian Robots may struggle to reach below 10 seconds for similar strokes.

Additionally, it’s worth noting that side entry models are specifically engineered for continuous high-speed operation. In contrast, a standard ‘off-the-shelf’ Cartesian model would be operating at the upper limits of its capabilities when running at such rapid cycle times.

Other factors to consider

Once you’ve confirmed the necessity for a specialized packaging-grade mold tool and identified the imperative of employing a side entry robot to meet your designated cycle time, what further factors warrant consideration?

- Consider the capabilities of your injection molding machine: inadequate plasticizing capacity or slow opening and closing speeds can hinder achieving your desired cycle time. Additionally, high injection speeds may be necessary, potentially requiring the utilization of accumulators.

- Factor in downtime: Recognize that machines and mold tools inevitably require maintenance, so it’s prudent to allocate time for these necessary tasks.

- Consider post-molding product handling: With the creation of a high volume of products, adequate provision must be made for post-molding operations such as bagging, carton packing, and collating. Additionally, it’s essential to factor in buffer considerations to ensure continuous molding operations even if downstream operator functions are interrupted due to breaks or other reasons.

- High-volume part production necessitates maintaining ample stock levels of raw materials and achieving the optimal balance between storage capacity and shipping requirements. Finding the right equilibrium between storage space and shipment logistics is crucial for efficient operations.

Other side entry applications & considerations

Indeed, side entry robots are better suited for In-Mold Labeling (IML) applications compared to Cartesian models. This is because side entry robots minimize movements of the foil, consequently reducing disturbance on the mandrel to a minimum. This results in enhanced precision and efficiency in the IML process.

In situations where headroom is limited, Cartesian solutions frequently encounter difficulties, whereas side entry units excel without such constraints. Although six-axis robots can address headroom issues, they struggle to match the high take-out speeds of side entry units. Additionally, their design necessitates even greater mold opening strokes, further complicating matters.

When it comes to applications requiring a stack mold tool, the side entry robot emerges as the clear leader in suitability. While there are Cartesian robots available for stack molds, their effectiveness still lags behind that of the side entry solution. Side entry robots, particularly those equipped with double arms, effortlessly handle stack tools, showcasing superior performance and efficiency in such scenarios.

Still not sure?

If you’re interested in exploring a specific application further, our experienced team is ready to assist you in finding the optimal solution.

Visit markrobotic.com to connect with our knowledgeable professionals and discover how we can meet your unique needs.

MARKROBOTIC LTD COMPANY Has more than 14 years of experience and is well known for high-performance IML ROBOT ,EOAT System , TOP ENTRY ROBOT , Handle Fitting Machines, Medical Automation Systems as well as innovative downstream solutions that include Product/Decoration Inspection, Assembly-and Box Filling Systems.

Headquarter of MARKROBOTIC is based in Istanbul /Turkey , providing superior service and greater overall value to a rapidly expanding global customer base.

For request IML ROBOT OR TOP ENTRY ROBOT you can contact with us : WWW.MARKROBOTIC.COM