What do Pick and Place Robot Do and How is Their Operation Defined?

Pick and place robots are automated systems designed for a specific purpose: to pick up an object from one location and accurately place it in another. These robots are commonly used in manufacturing, packaging, and assembly processes to streamline repetitive tasks.

What do pick and place robot do?

In straightforward terms, pick and place robots are designed to pick up items and relocate them. Their primary application is in high-throughput settings, such as the packaging, food, and beverage industries, where they play a crucial role in enhancing efficiency and productivity.

Types of pick and place robots:

-

Gantry Robots(Top entry robot):

The Top entry robot you’re referring to operate along three planes: X, Y, and Z. These robots are distinguished by their exceptional positional accuracy and the capability to traverse larger workspaces compared to many other pick and place robots. This characteristic makes them well-suited for applications that demand precise movements in multiple directions and an extended reach

-

Robotic Arms:

- Indeed, 4 , 5 and 6-axis robotic arms stand out as the most commonly employed pick and place robots, primarily owing to their versatility. Their remarkable freedom of movement makes them well-suited for applications demanding intricate and complex maneuvers. The ability to operate in multiple axes allows these robotic arms to handle a wide range of tasks with precision and adaptability.

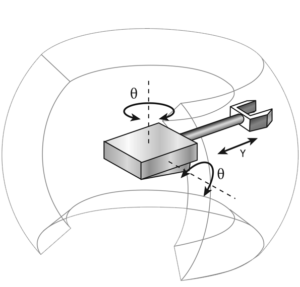

Delta-Robot

Polar-Robot

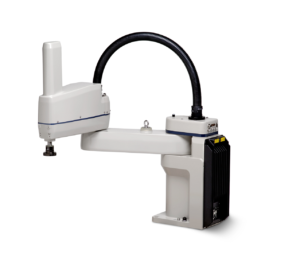

SCARA-Robot -Pick and place

Collaborative Robots (Cobots)

- Cobots, or collaborative robots, are specifically engineered to collaborate with human workers to enhance overall efficiency. In pick and place applications, these cobots often take on the role of AGV-style assistants, guiding human employees to optimal pick locations using the most efficient routes. However, it’s important to note that robotic arm-style cobots are also applicable in a diverse range of pick and place scenarios, showcasing the adaptability of these collaborative robotic systems.

Cobot Robot Read more: What are the different types of industrial robots?

-

Why should you use pick and place robots?

There are several compelling reasons to utilize pick and place robots in various industries. Here are some key advantages:

- Increased Efficiency:

- Pick and place robots automate repetitive tasks, leading to faster and more efficient operations. They can work continuously without breaks, significantly boosting production rates.

- Precision and Accuracy:

- These robots offer high levels of precision and accuracy in picking and placing items. This ensures consistent quality in product assembly and reduces errors.

- Cost Savings:

- While there may be initial setup costs, pick and place robots can contribute to long-term cost savings through increased productivity, reduced labor costs, and minimized errors in production.

- Flexibility:

- Pick and place robots can be programmed to handle a variety of products, making them adaptable to changing production needs. This flexibility is valuable in industries with diverse product lines.

- 24/7 Operation:

- Unlike human workers, pick and place robots can operate 24/7 without the need for breaks or shifts. This continuous operation enhances overall production output.

- Improved Safety:

- Collaborative robots, designed to work alongside humans, enhance workplace safety. They can take on repetitive or hazardous tasks, reducing the risk of injuries to human workers.

- Enhanced Product Quality:

- The precision and consistency of pick and place robots contribute to improved product quality. This is particularly crucial in industries where precision is paramount, such as electronics and pharmaceuticals.

- Optimized Material Handling:

- Pick and place robots can be integrated with conveyor systems and other automation components to optimize material handling processes. This integration streamlines the flow of materials within a production environment.

- Scalability:

- As production needs change, pick and place robots can be easily reprogrammed or adapted to handle new tasks. This scalability makes them suitable for evolving manufacturing environments.

- Competitive Advantage:

- Incorporating advanced automation technologies like pick and place robots can provide a competitive edge in industries where efficiency, precision, and product quality are critical factors.In summary, pick and place robots offer a range of benefits, including increased efficiency, precision, and flexibility, leading to cost savings and improved overall production outcomes. The decision to use pick and place robots is often driven by the specific needs and goals of a particular industry or manufacturing process .

You can see thıs video from Fanuc: