Multi-jointed Arm Robot: Explore the Various Categories of Industrial Robots and Their Utilizations.

Numerous manufacturing entities employ industrial robots like articulated arms to automate operations, enhance worker safety, and enhance production efficiency, all while reducing waste and operational expenses.

With the rising prevalence of industrial robots in manufacturing settings, there is a growing need for a diverse range of these machines to cater to various applications and industries.

In this article, we’ll delve into the diverse array of industrial robots available in the market, elucidating their operational mechanisms and highlighting the industries or tasks they are commonly deployed in.

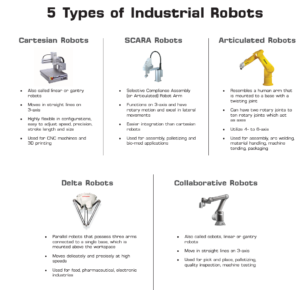

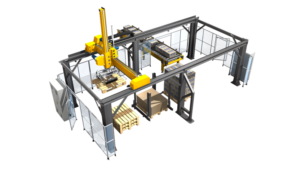

Cartesian robots, also referred to as linear robots or gantry robots, utilize three linear axes following the Cartesian Coordinate System (X, Y, and Z), enabling straight-line movements in three dimensions. This design facilitates movements in up and down, in and out, and side-to-side directions. Cartesian robots are highly favored due to their versatility, allowing users to adjust parameters such as speed, precision, stroke length, and physical dimensions.

Renowned for their adaptability, Cartesian robots find extensive use in industrial settings, often paired with CNC machines , IML ROBOT and 3D printers to streamline various manufacturing processes.

-

Articulated Robots :

Articulated robots bear a striking resemblance to the mechanical structure and movement pattern of a human arm. Typically, these robots feature a twisting joint that links the arm to its base.

The number of rotational joints within the arm can vary from two to ten, each acting as an axis and expanding the range of motion available. Most commonly, articulated robots are equipped with four or six axes.

These versatile robots find applications across various industries. Typical uses include assembly tasks, arc welding, material handling, machine tending, and packaging operations. Their ability to maneuver in multiple directions with precision makes them indispensable in numerous manufacturing processes.

-

SCARA Robots

SCARA, which stands for Selective Compliance Assembly Robot Arm or Selective Compliance Articulated Robot Arm, is commonly referred to by its acronym. These robots combine three-axis motion (X, Y, and Z) with rotational motion.

In contrast to Cartesian robots, SCARA robots excel in lateral movements, often boasting higher speeds and easier integration. They are particularly well-suited for a range of applications including biomedical tasks, palletizing, and assembly operations. Their versatility and agility make them invaluable assets across various industries.

-

Collaborative Robots

Collaborative robots (cobots) are lightweight robotic arms that handle a wide range of applications to automate repetitive tasks, usually conducted by workers. They are designed to share a workspace with humans, making automation easier than ever before, for businesses of all sizes and can be brought into play in a wide variety of applications .

Cobots are designed to share a workspace with humans, making automation easier than ever before for businesses of all sizes. All of these benefits have made our cobots a game-changer for a wide variety of applications.

Cobots are Collaborative robots that are cost-effective, safe, and flexible to deploy. Collaborative robots – or cobots – are making automation easier than ever, even for small and mid-sized companies around the world.

-

Delta Robots

Delta robots, also recognized as parallel robots, consist of three arms connected to a single base positioned above the workspace. This configuration allows for precise control over each joint of the end effector. With their dome-shaped work surface, Delta Robots are capable of operating gently and accurately at high speeds. They find widespread application in industries such as food processing, pharmaceuticals, and electronics for rapid pick-and-place operations, where speed and precision are paramount.

In summary, a plethora of industrial robots are developed by various companies, offering a wide array of options to enhance workforce efficiency. Whether it’s articulated arms, Cartesian robots, SCARA robots, cobot robots, Delta robots, or numerous others, integrating these advanced machines into manufacturing processes can significantly improve productivity and precision. The key lies in selecting the right robot for the specific application and industry requirements, leveraging their capabilities to streamline operations and achieve optimal outcomes.

MARKROBOTIC LTD COMPANY Has more than 14 years of experience and is well known for high-performance IML ROBOT ,EOAT System , TOP ENTRY ROBOT , Handle Fitting Machines, cobot robot , Medical Automation Systems as well as innovative downstream solutions that include Product/Decoration Inspection, Assembly-and Box Filling Systems.

Headquarter of MARKROBOTIC is based in Istanbul /Turkey , providing superior service and greater overall value to a rapidly expanding global customer base.

For request you can contact with us : WWW.MARKROBOTIC.COM